Products

Cable clips for fiber optic cables

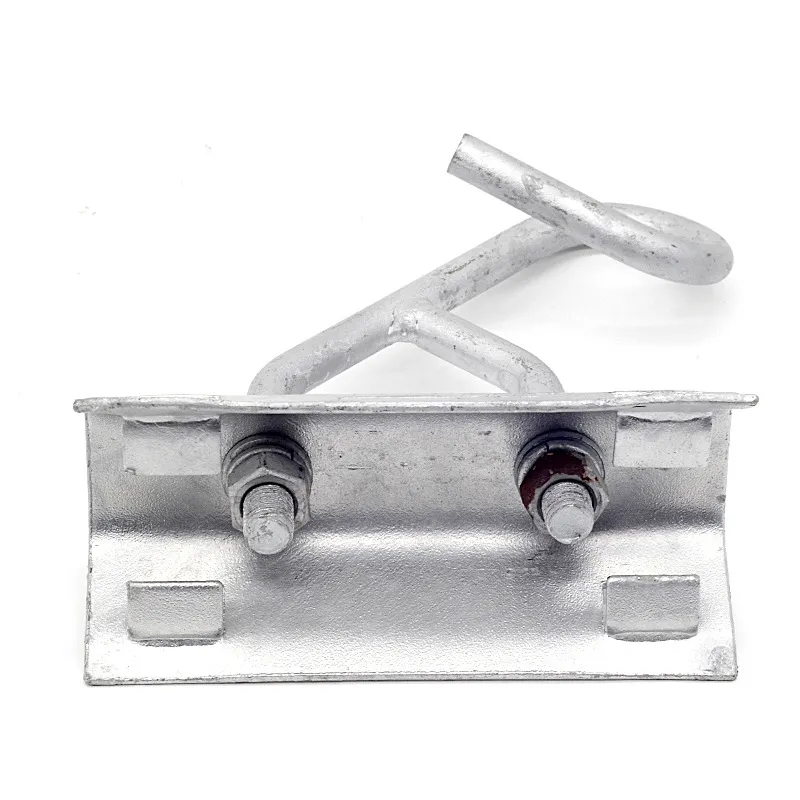

Product Description: A fiber optic cable mounting hook is a component for securing cables that combines the functions of “attaching to a bracket” and “hanging with a hook.” It is mainly used for routing cables indoors and outdoors. First, it fastens the entire struc...

Description

marker

Product Description:

A fiber optic cable mounting hook is a component for securing cables that combines the functions of "attaching to a bracket" and "hanging with a hook." It is mainly used for routing cables indoors and outdoors. First, it fastens the entire structure to walls, towers, or cabinets using brackets, then suspends the cables with hooks. This helps organize the layout of cables and provides stable support for them, making it convenient when multiple cables are routed in parallel.

Main Structure and Design Features:

The design of the fiber optic cable mounting hook is developed with consideration for "organized mounting of multiple cables" and "adaptability to various installation scenarios," ensuring a balance between stability and ease of use.

Main Structure:

It consists of two main components: a fixed bracket (a load-bearing base for attachment to walls/poles/cabinets) and built-in hooks (evenly distributed along the bracket for suspending cables).

The fixed bracket typically features a "strip" or "L-shaped frame" configuration with mounting holes (compatible with anchor bolts or cable ties). The built-in hooks have an arched design with notches spaced at regular intervals (e.g., 5 cm, 10 cm) along the bracket, allowing for the simultaneous mounting of multiple fiber optic cables.

Key Design Features:

The built-in hooks have a uniform inner diameter or graded sizes (e.g., suitable for both Φ12 mm and Φ16 mm grooves), allowing the use of cables with different outer diameters (such as telecommunications and power cables) to meet mixed installation requirements.

Brackets and hooks are mainly manufactured as one-piece castings (e.g., injection-molded plastic, metal stamping), eliminating joints, increasing overall load-bearing capacity, and preventing hook detachment. Rubber gaskets may cover the hook areas of some metal brackets to avoid direct friction between the fiber optic cable and metal, thereby protecting the cable sheath.

Fixed brackets can feature an "adjustable angle" design (e.g., hinged structures) to align the hook direction with the inclined mounting surface (e.g., slanted poles, wall corners), enabling horizontal or vertical cable routing.

Some models are equipped with "covers" or "latches." After the hooks secure the cables, these covers or latches can be fastened to prevent cable displacement caused by external forces (such as wind or contact with animals), as well as provide protection against dust and corrosion.