Cable hooks are essential organizational and fastening components used in the installation of power lines and telecommunication cables. They are primarily employed to neatly suspend or secure cables and optical fibers on supports such as cable trays, poles, or walls, preventing tangling, abrasion, or exposure to external tension. Simultaneously, they facilitate subsequent maintenance and repairs, making them critical tools for ensuring orderly cable management and safe operation of lines.

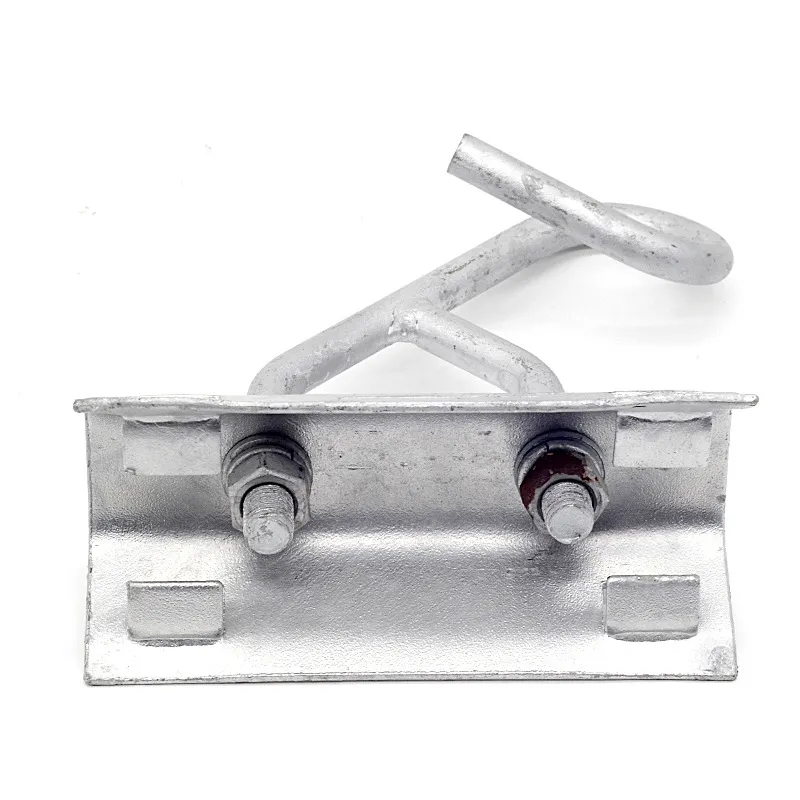

Manufacturing Process: Plastic hooks are produced via injection molding, enabling mass production with high dimensional accuracy. Metal hooks undergo stamping and bending processes, with edges chamfered to prevent cable damage. Surface treatments include hot-dip galvanization or powder coating for metal variants, and UV-resistant coatings for plastic types, extending their service life.

Core Structure: Consists of a "hook body + fastening mechanism." The hook body features a curved or U-shaped channel with a smooth interior surface (some include anti-slip ribs) to prevent cable slippage or abrasion. The fastening mechanism includes screw holes, adhesive bonding, or snap-on designs for installation on various substrates.