Fiber optic hooks are essential components in fiber optic communication networks, used for securing and protecting optical fibers. Below is a detailed description:

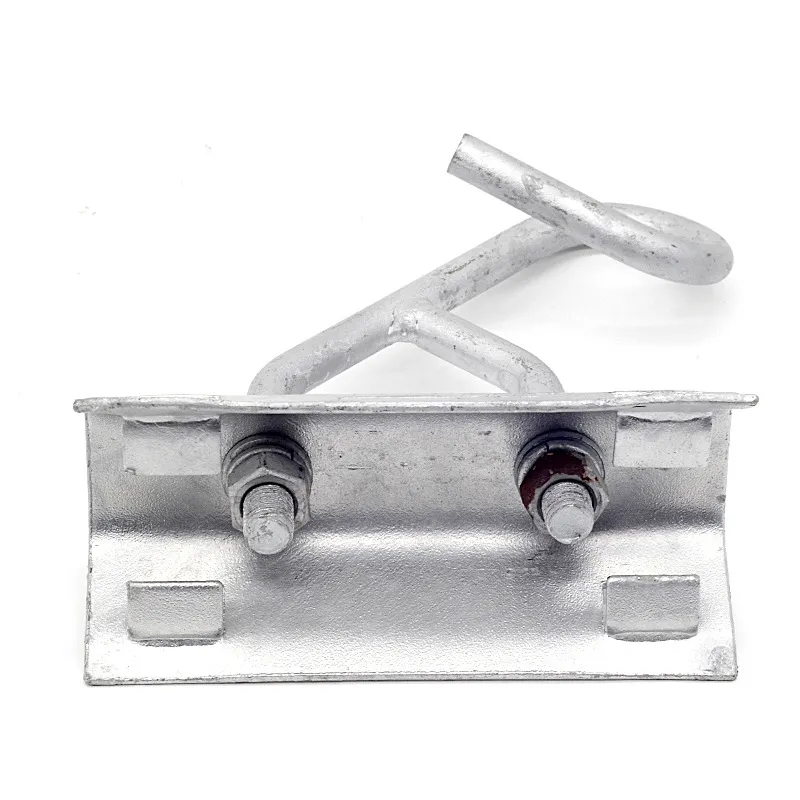

Fiber optic hooks typically consist of two parts: a mounting plate and the hook itself. The mounting plate features fixing holes, allowing it to be secured with bolts or similar means to structures such as communication cabinets, power line poles, or walls. The hook is usually U-shaped and designed to support fiber optic cables. Some fiber optic hooks include connecting slots or locking blocks, facilitating the connection and assembly of multiple hooks.

To ensure high performance, fiber optic hooks are generally made of high-strength plastics such as polypropylene (PP) or polyethylene (PE). These materials offer corrosion resistance, aging resistance, and light weight. For applications requiring higher strength, metal materials such as stainless steel may be used.

Based on application scenarios, fiber optic hooks are categorized into types for indoor, outdoor, or special environments. Indoor hooks are compact and easy to install, ideal for stable environments like homes, offices, and indoor spaces. Outdoor hooks exhibit excellent weather resistance and impact strength, withstanding unpredictable natural phenomena affecting fiber optic cables. They are commonly used in outdoor fiber optic networks.

Fiber optic hooks securely fasten cables in designated positions, effectively minimizing movement or breakage caused by environmental factors. This enhances the stability and reliability of fiber optic networks. Their modular design simplifies maintenance and management, enabling quick replacement or repair in case of malfunctions.