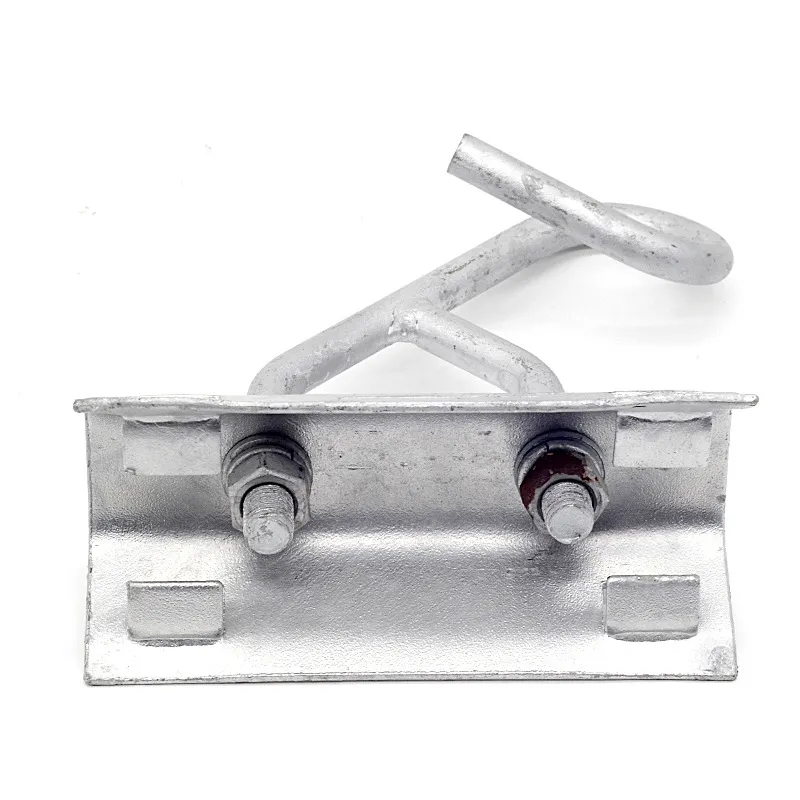

Tiger Head Grip Rod is a widely used tensioning tool, named for its end that resembles a tiger's head. Below is a detailed description:

Typically consists of a rod and a tiger head grip socket. One end of the rod is threaded to connect with other components or engage with nuts for fixation or length adjustment. The opposite end connects to the tiger head block. The top sides of the block have grooves, and the block itself features a through-hole passing through these sides. During operation, the cable passes through this hole and engages with the grooves, serving to guide and secure the cable.

Materials and Specifications:

Materials generally include high-quality steels such as Q235, 35#, and 45#. Some high-performance products use alloy steels like 40CrMo or 35CrMo. Common specifications include diameters of 5/8 inch, 3/4 inch, and 1 inch, with lengths of 6 inches, 9 inches, and 12 inches. Custom lengths can be manufactured for special orders.

To enhance corrosion resistance and service life, surface treatments such as hot-dip galvanizing, electro-galvanizing, or powder coating are typically applied.

Tiger head grip rods are widely used in power, construction, mining, and related industries. For example, in the power industry, they are often used to secure ground anchors for transmission line towers. Steel cables or pre-twisted tension clamps are connected to ground anchors using tiger head grip rods, ensuring the stability of transmission line towers.

Their design ensures even distribution of cable tension, effectively dispersing pulling forces to prevent cable failure due to stress concentration points. They guarantee safety and reliability under significant tensile loads, demonstrating high tensile strength.