Products

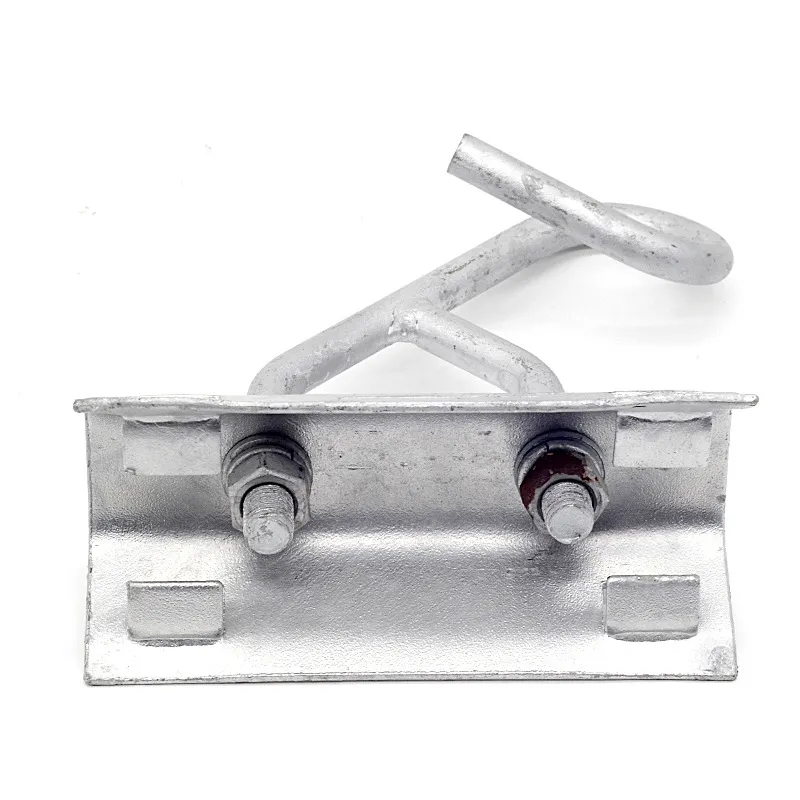

High-strength square head bolts

Product Description: High-strength square head bolts are high-strength fasteners with a square head. Their main advantages lie in the ease of positioning the square head and excellent anti-rotation stability. They are suitable for applications requiring high installation stability and load...

Description

marker

Product Description:

High-strength square head bolts are high-strength fasteners with a square head. Their main advantages lie in the ease of positioning the square head and excellent anti-rotation stability. They are suitable for applications requiring high installation stability and load-bearing capacity, especially in confined spaces where wrenches need to apply force from the side.

Main Structure and Design Features:

The structure of square head bolts is focused on "reliable fixation" and "ease of operation", which significantly distinguishes them from standard hexagonal head bolts.

Main Structure:Consists of a square head and a threaded rod. The four sides of the head serve as bearing surfaces, and the rod usually has full or partial threads (the latter is used on longer rods to enhance shear resistance).

Key Design Features:

The head thickness is usually greater than that of standard bolts. Combined with the square structure, this allows the bolt to withstand higher tightening torques, preventing head deformation or slipping during installation.

Some models have pre-processed mounting holes or recesses in the head. This facilitates precise alignment with the fastened component, preventing bolt displacement in vibrating environments.

The shank and head are often forged as a single unit without welded connections. This ensures uniform mechanical properties throughout the bolt, minimizing the risk of failure under load.

Materials and Strength Classes:

As high-strength fasteners, material composition and strength classes directly determine load-bearing capacity, meeting the requirements of medium and high loads.

Main Materials

The main alloys include alloy steel 40Cr and steel 20MnTiB, hardened by quenching and tempering to improve strength and toughness.

For highly corrosive environments, 304/316 stainless steel or special anti-corrosion coatings such as Dacromet or hot-dip galvanizing are used on the surface of alloy steel, making them suitable for applications in the chemical and marine industries.

Strength Classes

Common classes include 8.8 and 10.9, while 12.9 is used in some ultra-high pressure cases. The class values are as follows:

Taking class 10.9 as an example: "10" indicates a minimum nominal tensile strength of 1000 MPa, and "9" indicates a yield strength to tensile strength ratio of 0.9, meaning the yield strength is ≥ 900 MPa.