Material: Typically made of high-quality low-carbon steel (e.g., Q235B) or alloy steel to meet mechanical strength and electrical performance requirements. Stainless steel is used for certain specialized applications.

Structural Features: The steel foot consists of three parts: an upper conical head, a central cylindrical rod, and a lower spherical base. The entire upper conical head is coated with cement adhesive, connecting it to the porcelain body and iron cap to form an elastic system for transmitting mechanical forces.

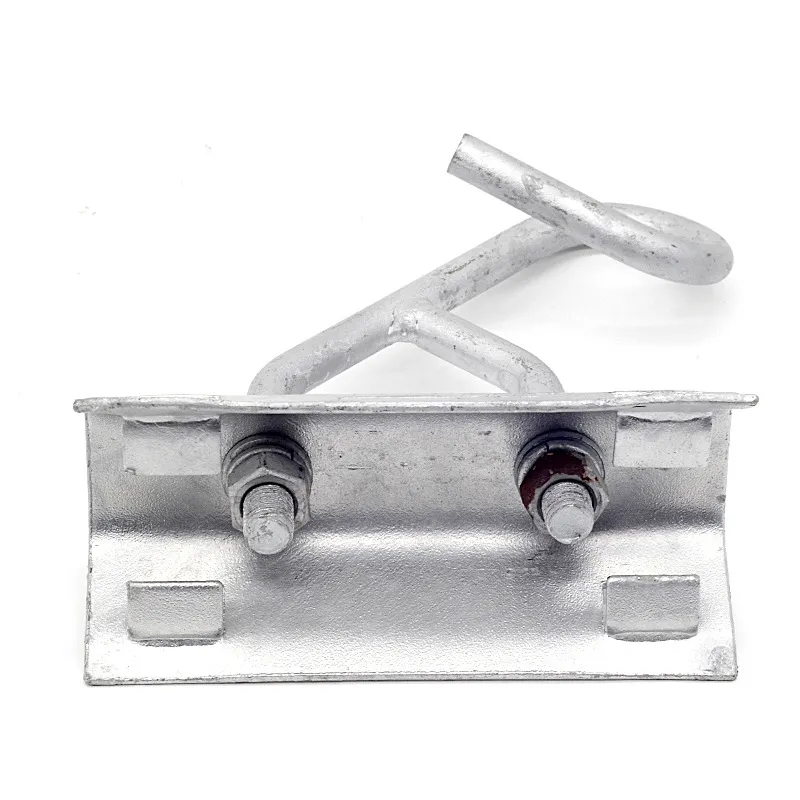

Surface Treatment: To prevent corrosion and extend service life, steel feet undergo hot-dip galvanization. According to relevant standards, the average thickness of the zinc layer must reach 85 μm, with a minimum local thickness of ≥70 μm.

Function: Located at the base of insulators, steel feet secure the insulator to tower or equipment supports. They withstand the weight and tension of conductors, as well as external impacts, while maintaining electrical insulation between the insulator and the support structure.